Behind every block or cutting board produced by Euroceppi lies a well-organized production chain, the result of over a century of experience and innovation. Our company structure has been designed with a clear goal: to ensure efficiency, linearity, and quality at every stage of the process. From the east gate, where raw materials enter, to the west warehouse, where the finished product leaves, each step is meticulously organized to offer our customers the very best.

Raw Materials: From Panel Arrival to Pre-Production

It all begins with the arrival of high-quality wood, carefully selected from our trusted suppliers. These panels are stored and prepared to enter the heart of the production process.

The first phase involves constructing the block, a crucial step in creating the product’s foundation. This stage requires precision, as each panel must meet strict quality standards to ensure the strength and durability of the blocks over time.

Gluing and Pressing: Perfect Bonding

The next step is gluing, where the panels are combined to create a solid and uniform structure. This phase is followed by automated pressing, ensuring optimal surface adhesion. Our advanced technology guarantees that every detail is taken care of, preventing structural imperfections.

After leaving the press, the pieces begin to take shape: the material is compact, durable, and ready for the next processing stages.

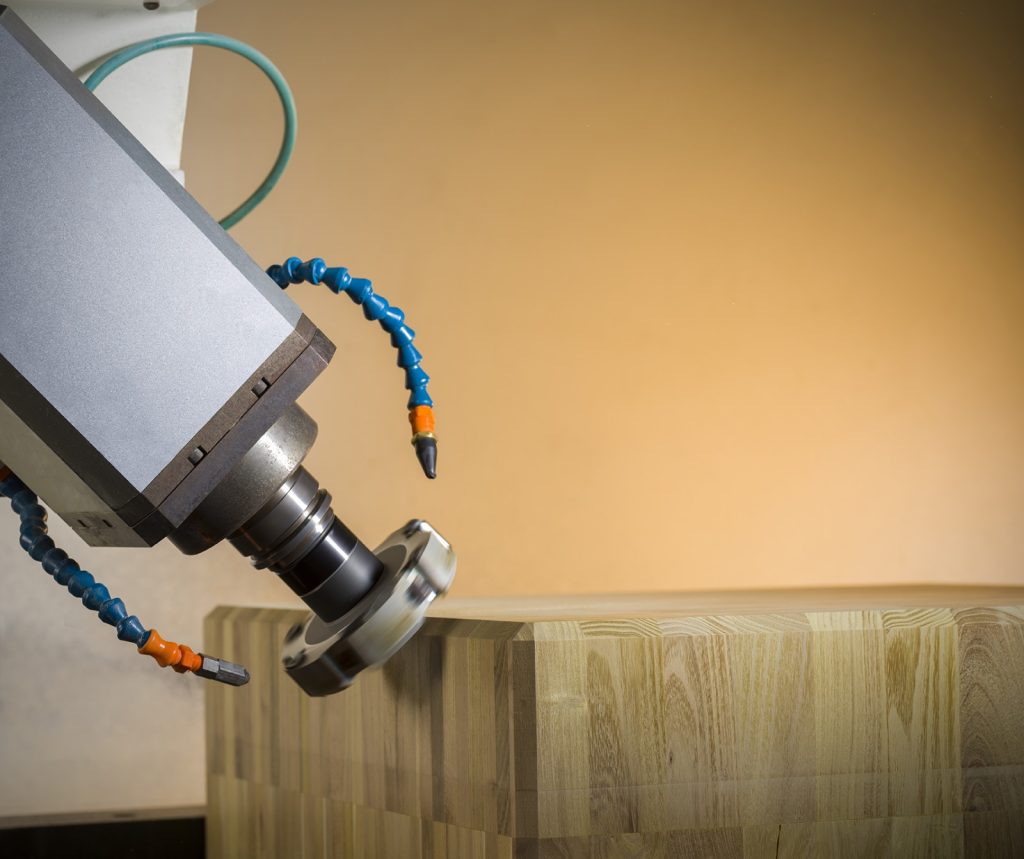

Milling: Precision and Detail

One of the most delicate stages is milling, carried out with state-of-the-art machinery. This process defines the dimensions, profiles, and details of the blocks, ensuring a flawless finish. Each piece is crafted to meet the aesthetic and functional demands of the professional market.

Sanding and Preparation: The Perfect Finish

After milling, the blocks undergo sanding and filling, two fundamental steps to eliminate any imperfections. The surfaces are treated to achieve a smooth, uniform texture that is pleasant to the touch.

Varnishing: Elegance and Protection

Varnishing is the moment when the product takes on its final appearance. We use durable, safe, and certified varnishes that not only enhance the natural beauty of the wood but also protect the block, ensuring long-lasting durability.

A Linear and Optimized Production Process

Our production line, organized in a linear manner, is designed to optimize time and resources. Each stage of the process runs seamlessly, thanks to the perfect integration of automation and craftsmanship. The result is a product that blends tradition and innovation, ready to meet the demands of the most discerning customers.

With Euroceppi, every block is not just a work tool but a product of excellence, created with passion and dedication.